Redefining hand protection

The All New Graphex™ Range Engineered using nanotechnology to create a carbon-based yarn, combining the highest level of cut resistance available with exceptional comfort, fit and dexterity.

Engineered with nanotechnology for carbon-based yarn

Highest cut protection

available reaching

Cut Level F

Certification by BSI Group to UKCA and CE hand protection standards

The use of carbon allotropes in the Graphex yarn is the innovative component ensuring consistency in performance. The structural stability provided by the allotrope allows for the production of a yarn that is thinner, lighter and stronger than traditional materials in cut resistant gloves.

Increased cut resistance. Exceptional abrasion resistance. Unparalleled dexterity.

These are the cornerstones of the Graphex® range, only achieved through research advancements in nano-technology. The traditional trade-off of dexterity for cut resistance is a fallacy of the past.

Certified under European Standard

EN 388

Graphex recognises that the use of mobile phones and tablets is now extremely common in the workplace, whether it be in the office or onsite.

We have added a touch of genius to the entire range by allowing the wearer to leave their gloves on to answer calls or emails as they need to, eliminating the time consuming process of taking the glove off and more importantly reducing the chances of a workplace hand injury.

The Graphex® range not only protects the wearer from potential hand injuries, it also ensures skin health through Reach Compliance. This compliance ensures Graphex® gloves have a safe pH level and contain no azo dyes or residual chemicals that can cause skin irritation. In addition, the Graphex® range also offers UPF50+ sun protection and is fibreglass free. We really do care.

Certified to European Standard

EN ISO 21420:2020

Certified to European Standard

EN ISO 21420:2020

Compliant under EN 1186

Graphex® has entrusted Notified Body, to ensure to audit and certify both the manufacturing process and the products performance testing adherence to standards claims cannot be independently verified.

Asking a trusted and independent notifying body to certify the mechanical scores guarantees that the scores are accurate and performance will be to this certification.

The entire Graphex® range is certified to European Standards.

As far as cut resistance is concerned, the Graphex® glove range offers the utmost protection from Level D to Level F under EN 388:2016. However Graphex® recognises one glove does not cover all applications so we have created an entire range to service industries from General Assembly through to Oil & Gas. Whether you need a liquid-resistant glove or TPR back of hand protection, there is a Graphex® glove that will meet your requirements.

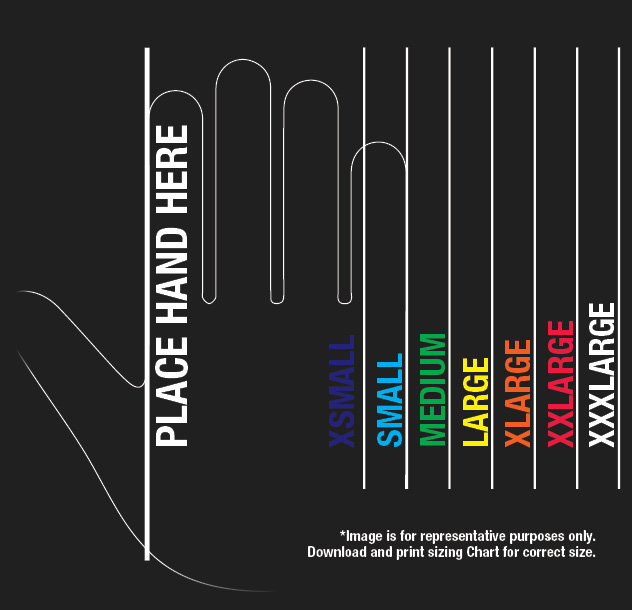

The most important variable which will impact the comfort of your Graphex® glove is the size. Choosing the right size is critical in ensuring that they meet their safety expectations. Gloves should be a tight fit with no loose sections, acting like a second skin on your hands.

The Graphex® range of cut gloves offers the highest level of cut protection available, and we are happy to demonstrate this to you. Using a cut machine similar to the TDM-100 machine used by certified laboratories to conduct EN ISO 13997 cut tests, we can visit your workplace to demonstrate how Graphex® performs against the gloves currently being worn by your employees.

Workplace hazards are commonplace. Injury and illness are very expensive to businesses, costing the Australian economy an estimated $62 billion each year. Identifying hazards is the critical component of PPE selection and can reduce a business’s expenditure significantly. Hazards that may be encountered include mechanical, biological, chemical, heat, cold and abrasive surfaces. If these cannot be removed from the workplace, the risk of injury can be substantially minimised through the correct selection of PPE, ensuring the job can be completed safely.

As a market leading designer and manufacturer of personal protective equipment, Force360® is at the forefront of delivering innovative products and services to various industries around Australia. To manage wearer safety is to manage the correct use of personal protective equipment by ensuring its suitability for the specific application. The 360applied® program helps tailor the PPE selection to your business, providing task specific solutions for your employees.